Mining Element has expanded its line of conveyor components

In 2021, Mining Element conducted the first set of tests on its conveyor components. New products include belt cleaners and cradles – they aim to increase the productivity of the conveyor. The company has also released impact bars and pulley lagging (lining) that prevent conveyor breakdowns.

Conveyor Belt Cleaners

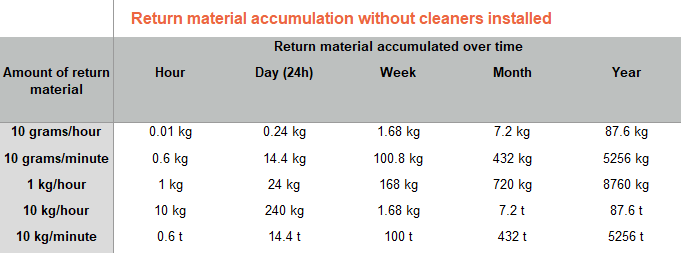

Enterprises often face the problem of reverse material transfer when transporting raw materials on a conveyor belt, which creates a whole range of problems. Firstly, the material sticks to the rollers over time and jams them. If the problem is not fixed promptly, it can lead to a roll-off of the conveyor belt or its rupture.

Secondly, raw materials fall into the sub-conveyor space, forming debris and dust. Mechanics are forced to clean up spills with improvised means. It is necessary to stop the conveyor at a time which is unscheduled. Indeed, this is a time when the company loses profit. In a year, the amount of return material falling under the conveyor can reach up to five tons.

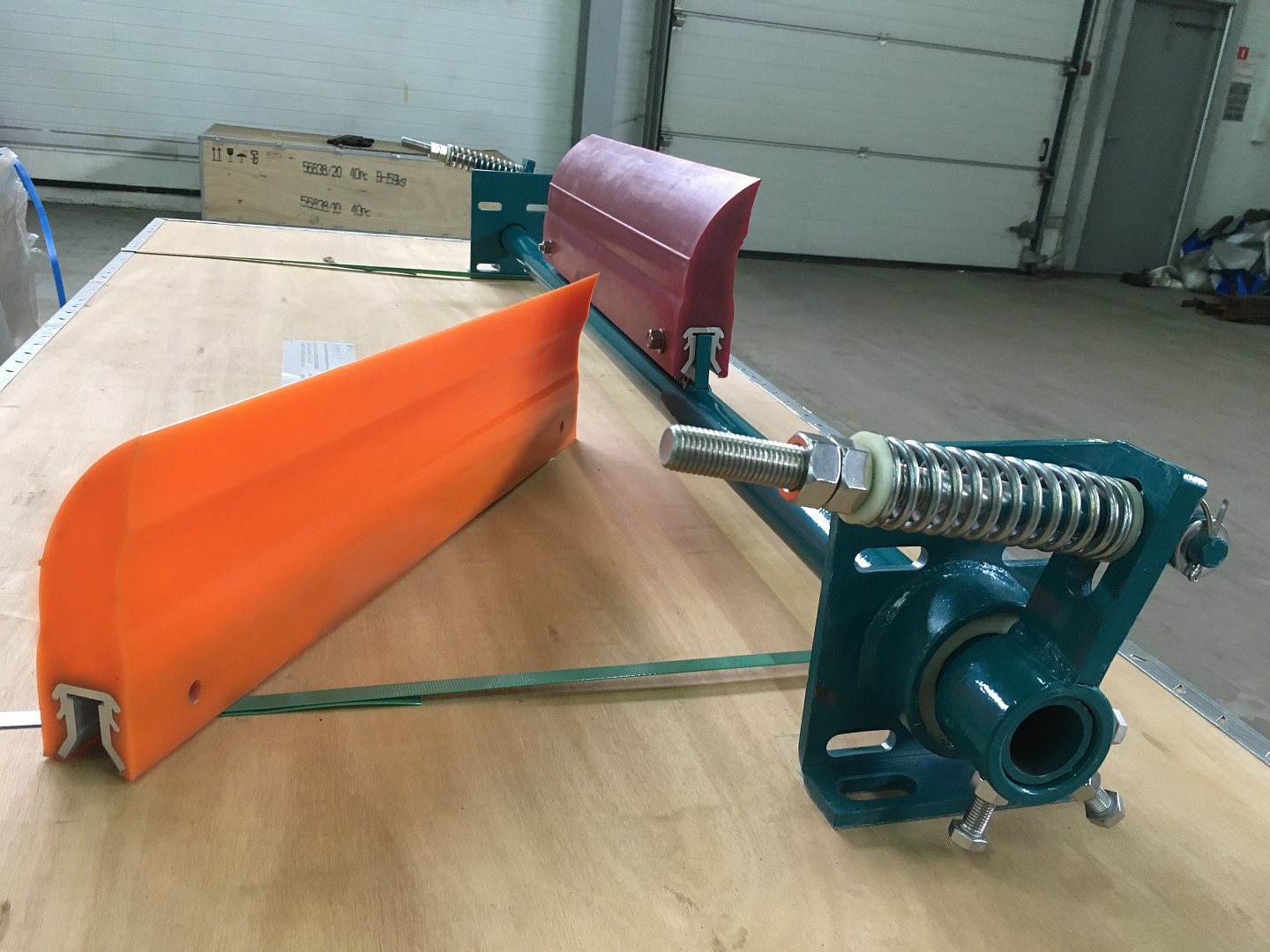

Conveyor belt cleaners, the so-called ‘scrapers’, prevent the reverse transfer of material. Mining Element selects cleaners according to the operating conditions and the type of transported raw materials. This helps them to achieve a high degree of cleaning and subsequently maximizes the life of the wear parts.

.jpg)

.jpg)

"We’re able to choose the most suitable material for replaceable cleaner blades. At the same time, we’re always ready to supply blades for pilot tests in order to adjust the materials for future deliveries, if necessary," said Alexander Kuznetsov, a specialist in the Conveyor Components business line at Mining Element.

The simple and reliable design of the cleaners simplifies their installation on the conveyor and allows one to adjust the clamping force of the blade to ensure correct operation throughout its entire service life.

Mining Element’s replaceable blades can be installed on any structure. If a cleaner fr om another manufacturer has been installed on the conveyor, Mining Element will add the appropriate transition elements to the kit.

Regarding Mining Element’s scrapers for belts, there are primary, secondary and belt plough cleaners. The former kind remove most of the return material and return it to the hopper to join the main flow of the transported raw materials. The secondary scrapers clean the belt. Ploughs push pieces of material fr om the inner surface of the return run, preventing them from falling between the belt and the pulley.

Pilot tests of conveyor belt cleaners, which took place from 2021 to 2022 at cement production plants, showed that the life capacity of Mining Element’s blades is comparable to the operating time of OEM-made blades working under the same conditions. Importantly, Mining Element’s blades come at a significantly lower cost.

"In 2022, we plan to continue pilot tests not only in the cement industry but also in the mining industry. In parallel, we will offer a new unified design of cleaners that covers most of the needs of customers," Kuznetsov shared.

Impact bars and cradles

Impact cradles in combination with Element impact bars dampen the impact energy of the material when loading onto the conveyor belt and increase its service life as a result.

The bar consists of a rubber base with an aluminium fastening profile and an upper lining made of high-molecular polyethylene.

.jpg)

The durable rubber base reduces the impact energy of the loaded material. The lining is made of high-molecular polyethylene, and due to its low coefficient of friction, it allows the conveyor belt to slide freely on it without abrasion.

Mining Element offers standard impact cradles and those from bespoke design, taking into account the specifics of the conveyor’s operation. For example, there might be an elongated version of the table consisting of more than one section or a cradle with a specific number of shock-absorbing rollers.

Pulley lagging (lining)

Pulley lagging increase the coefficient of friction between the belt and the pulley, thereby eliminating slippage, especially at high speeds of pulley rotation. In addition, thanks to the lining, the belt stretches less, which means that its movement retains straightness.

Mining Element offers two types of lining: quick-replaceable on welded guides and those with a binding layer. Both options are available in rubber and rubber-ceramic.

.png)

The quick-replaceable lagging on welded guides is suitable for all types of pulleys: drive, tension, and deflecting. This is indispensable for pulleys installed in hard-to-reach places, as well as in cases wh ere readjustment with minimal downtime is necessary.

.png)

The guide elements of the lagging and slats are made in the form of runners, which makes it easy to remove worn-out linings by simply sliding them along the pulley. It is easy to install and change them without the need to remove the pulleys.

Lagging with a binding adhesive layer are used wh ere waterlogging, dirt, material abrasiveness, icing and difficult operating conditions are present. The ceramic elements retain a high coefficient of friction with the rubber band, which guarantees the reliable operation of the conveyor. The lagging firmly adheres to the surface of the pulley just 8 hours after the completion of the relagging work.

To select conveyor components for specific operational conditions, fill out the appropriate questionnaires and send them to us either via the form on our website or by email: con@miningelement.com.

We use cookies to enhance your browsing experience, analyze site traffic and serve tailored advertisements. By continuing to browse or closing this banner, you consent to our use of cookies. Read more about how we use cookies.Cookie Policy